So this is my very first wood working project that I completed on my own!! I’ve done some projects with the help of family members, but living over 400 miles from them, makes it difficult for them to come up for every project.

I got the idea, first of all it is all over Pinterest, and secondly, I really needed somewhere to keep my sewing machines when I am not using them. Typically I store them under my desk that I sew at, but then there are cords everywhere, or else I will accidently kick one. It is just not ideal. My husband and I recently moved our bedroom upstairs in our house and I decided to move my sewing room downstairs. This room is the perfect size and the location is excellent. A lot of the time, I would go upstairs to sew and I would feel very antisocial in my own home. Typically Josh would be in the living room watching/playing something sports related, so I would bring my sewing stuff downstairs….. which then would turn the dining room into a disaster because I would continuously bring stuff down one by one and then never take it back upstairs.

Anyway, onto the tutorial…

*Note: Keep in mind that I am not an expert. I have a basic knowledge of power tools, but as the saying goes, “There is more than one way to skin a cat”. (Sorry to my vet school sister for that analogy).

I started off by figuring out where I wanted the shelves to go. There is a small spot between the window and the corner that juts out, so I figured it would be the perfect place. Plus, it was roughly the size of my sewing machines. (I didn’t get a before picture, but you will be able to see what I’m talking about in the pictures below.)

I didn’t really plan out how I wanted to do it because I figured things would change as I went along, which they did. I initially wanted to have 5 small shelves going up, but after I got my first one up and put a sewing machine one it, I decided to cut back to 4.

I started out by getting 3 2x4x10 boards made of pine. These run about $4ish a piece. I chose 10 feet because I estimated my shelves being about 24 inches (you will have to parden the inches talk, I’m still in sewing mode) wide and about a foot deep. It was also a good length that wouldn’t stick out of the rear of our car too much. I ended up only needing 2 of them though.

Next I cut 5 pieces (I cut 5 because originally I was wanting to make 5 shelves) of the wood 24 inches long. The math actually came out perfectly and I got 5 perfect 24 inch boards out of my 10 foot board.

This is a saw that my dad gave me to use. It wasn’t until I was almost done that I realized it is a smidge off, as in like 1/2 a degree. Fortunately ended up not being that big of a deal, but when you looked at them up close, you can definitely tell they are slightly slanted.

Also, funny story about that saw… I texted my dad and told him that I would have to rig up something for the saw dust because after every cut, I would get showered with it. Visual picture, imagine me cutting the boards and then running away before gravity pulled the saw dust down on top of me. Anyways, he said that he has the attachment at one of his houses and hopefully I will get it very soon.

After I cut the 24 inch boards, I cut the next 2×4 into 10 inch pieces, making enough so that each 24 inch board, would have 2 10 inch boards to attach to it.

The goal of the next step, is to attach the boards so they make the shape of a “U”. You can do this before or after you attach the 24 inch board to the wall. I ended up changing the way that I attach the boards. At first, I would press the boards against the ground and put a screw in the back of the 24 inch board (the side that would go against the wall), but that ended up not being quite as sturdy as I wanted it to be.

Once I had screwed those boards on, I went ahead and found the studs in my wall. I first tried the “knocking” method, but it seemed like the studs were too far apart. After a phone call to my dad, he suggested me going outside and finding where the screws were on the side of the house (we have a wood house) and that would be where the studs were. Sure enough, there was a screw 28 inches from the window. I went back inside and measured 28 inches from the window and then did the “knocking” method again, and there was my stud. I did find a really clever way to find a stud on YouTube by using a magnet. I didn’t actually try it, but it definitely looks like it could work. Warning, that guy is super quirky, but you should totally go check out his video.

I lined everything up by lining up one piece and marking where the studs were on that one piece. I then went back to the other 3 pieces and made the same marks. I also took a small drill bit and drilled 4 holes on each side, where the screws were going to go to mount it to the wall.

I then screwed the mounts onto the wall. I used a leveler to make sure they were lined up straight and then screwed them in. I totally used my foot to hold up the bottom one and then I figured that it was best that I get a little bit of help holding it while I screwed it in.

By this time, as you can tell by the “not scraped yet” windows, it was getting pretty dark and I decided to go ahead and close up shop for the day.

The next day, I decided to go to Lowes and pick up a new toy. That new toy was the Kreg Jig R3. I had heard of it from April Wilkerson who has an awesome YouTube channel and blog to go along with it. The Kreg Pocket Jig video was what introduced it to me and then after a little bit of searching, I discovered that I NEEDED to have it.

I picked this one up because I thought that it was very versatile and thought it would be perfect for what I had in mind. Let me tell you, it is AWESOME and so easy to use!!!

I got a 90 degree angle clamp, which does the job that I need it to do, to hold the jig to the board. Then I just screw the pocket holes in.

Like I said…. AWESOME!!!

It was also handy because I could go ahead and screw the 24 inch board to the wall and then come back later on and attach the 10 inch boards, however I didn’t do that at first.

Either way was super easy for get the boards attached to each other.

Look at how cool this clamp is!! It fits into one of the pocket holes and then clamps it to the second board. (Yes, I totally did this at the kitchen table.)

So I finally got all 4 pieces attached. You can see the part that juts out in the corner in this picture. I’m trying not to reveal too much of that room because it is still pretty messy from the move.

I ended up attaching a third board to the bottom two just to give it a little more support.

While at Lowes, I also picked up 2 pieces of 24×48 inch particle board. Plywood would have worked as well, but because this was going to be inside and the pieces I was using wasn’t going to be that big, I went ahead and used the particle board. Plus it was also cheaper.

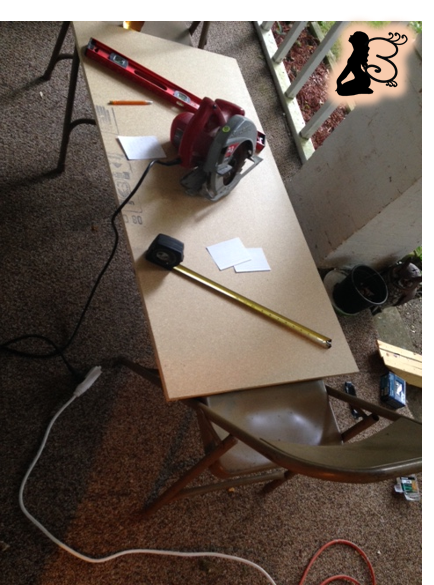

Don’t you like my chair-like saw horse? I totally cut these boards on my carpeted from porch. It’s ok. It’s nothing that a shop vac can’t take care of. ; )

I was careful to make sure I measure each one and then cut each one accordingly. I did have a hard time figuring out which piece I wanted to overlap which piece. I knew I wanted the front cover to overlap all sides, but I wasn’t sure about the top and the right side. I didn’t do a cover for the left side because I figured you wouldn’t be able to see it and the part that you could see, was just the cover from the other side. All of the top pieces ended up being roughly 25×12 inches.

I did have a little bit of problem trying too attach the 2nd from the bottom on. For some reason I would not lay flush. I ended up taking that entire piece off and pulling off the right side. With only the middle and left support attached, I went ahead and screwed the top cover on. I then went and drilled pocket holes into the remaining board and the reattached it to the rest of the piece.

After the top cover was attached, I went back and attached the left side cover. By this point, it was almost finished and all I had to do was attach the from cover, and maybe a bottom cover to the shelves.

I went ahead and made the front cover all the same size. I figured that it would be a lot more noticeable for them to be different sizes than for it to hang off the bottom 1/4 of an inch.

So here I am right now…… I’m not sure if I want to paint them white or Modge Podge some fabric over them….. or maybe paint some type of stencil on it.

I do know that I love not having my sewing machines on the floor under my sewing table.

*Note: Please ignore the mess and the pain on the windows and the messed up blinds. This room is definitely a work in progress and it is definitely getting there. I am so in love with the progress so far.

*Note #2: I am in no way affiliated with Kregg. It was just the brand I had heard of so I decided to go along with them.

I’ll be back at a later date to post the 100% finished project, but it wouldn’t be me if I didn’t complete it 90% and then put it down for a bit.

Until next time,

Brittany

Great job!

LikeLiked by 1 person

Thanks!! 🙂

LikeLike